Further ahead in eco-sustainability

COOMI has undertaken an articulated development activity with the aim of increasing the knowledge to obtain new applications in the industrial and technological fields.

Pyrolysis

The pyrolysis process allows the disposal of waste with high energy recovery, without solid and gaseous pollution. Today the ''pyrolysis'' of waste is a healthy alternative to the use of traditional incinerators (expensive and with heavy maintenance); while the evolution of waste disposal is reached through the use of pyrolytic ovens, much more efficient equipment with very low maintenance.

This type of plant eliminates waste through a process of thermochemical decomposition of organic materials, obtained by applying heat in a reducing environment (complete absence of an oxidizing agent such as oxygen). The heat supplied in the pyrolysis process breaks down the original chemical bonds of the material, forming simpler molecules.

Pyrolysis is an energy cycle capable of disposing the waste produced directly on site without having to depend on landfills. The result is energy in a much less polluting form, if compared to the one produced by fuels of fossil origin.

Gasifiers

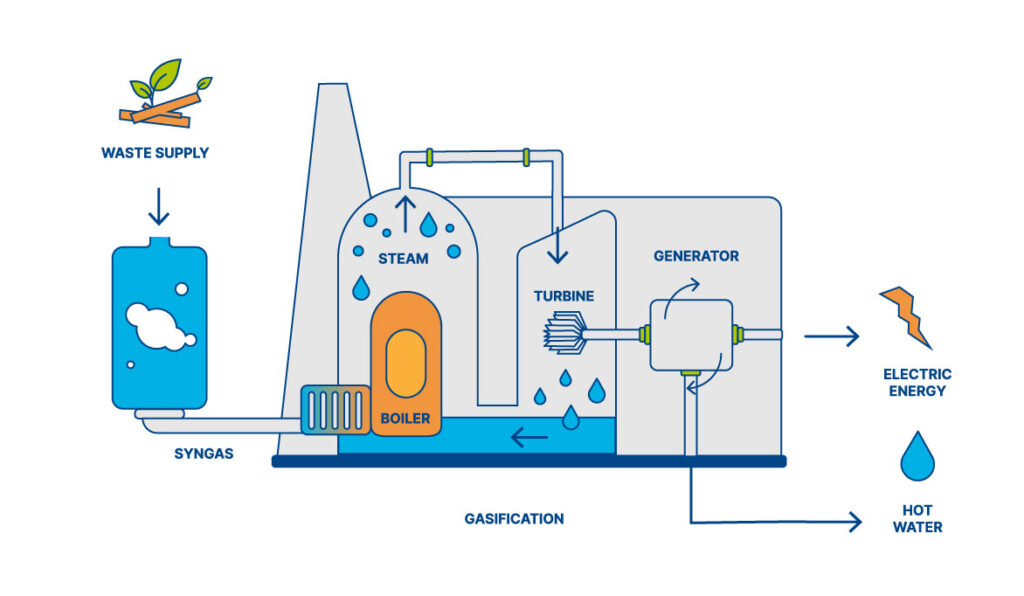

Gasifiers are plants that generate energy and hot water thanks to the incineration of waste from unsorted collection, with a high calorific value, intended for MBT (Mechanical Biological Treatment) or CWPP (Crushing and Waste Packaging Plant) plants.

The gasification system was born in Japan and has also been in use in Italy for some years now. These plants implement heating in nearly anaerobic conditions by exploiting molecular dissociation/pyrolysis to transform the Solid Secondary Fuel (SSF) into gas: the long carbon chains are split into molecules such as carbon monoxide, hydrogen and methane, which will generate a synthesis gas called Syngas.

The gasification system was born in Japan and has also been in use in Italy for some years now. These plants implement heating in nearly anaerobic conditions by exploiting molecular dissociation/pyrolysis to transform the Solid Secondary Fuel (SSF) into gas: the long carbon chains are split into molecules such as carbon monoxide, hydrogen and methane, which will generate a synthesis gas called Syngas.

en

en  it

it